Search results for: 'gasket-mw g'a=0'") ORDER BY 2319-- pjjo''

- Related search terms

- GASKET-MW G&H 20IN BUNA

- gasket-mw g

- gasket-mw g''A=0

-

Fuji Temp & PartsThe Fuji controller receives information from the temperature sensor and sends open/close signals to the Heat Transfer Jacket solenoid valve. It can also operate direct fire Burners/Immersion Heaters/Etc. Learn MoreAs low as $198.00

-

ADAPTER-E33208 CLAMP ADAPTER ASEPTOFLEX VARIO 1.5IN TC 316LADAPTER-E33208 CLAMP ADAPTER ASEPTOFLEX VARIO 1.5IN TC 316L Learn More$67.50

-

(2) Cross Arm Assembly 3-ArmHeavy-duty 7ga outswing door and wing nuts swing free and clear of opening. . Triple cross arm for strong seal. Learn More$624.90

-

Parts for Top Outswing ManwayReplacement components for JVNW top mount manways in sizes 10", 18", 20", or 24" are available. Please note that manway versions may vary over time. For accurate parts information, kindly get in touch with us. Customized door plates are crafted upon request. Feel free to call for pricing details and lead time. Learn MoreAs low as $3.00

-

Sprayballs & PartsSprayballs are used either for dispersing cleaning solution into a tank, or sparging onto a lauter tun grain bed. The sprayball slips onto tubing with a hairpin clip. 2-1/2 in. sprayballs slip over 1 in. tubing and will clean up to 5 foot diameter vessels. 3-1/2 in. sprayballs slip over 1-1/2 in. tubing and will clean up to 10 foot diameter vessels. Optimum operation: 40 GPM @ 25 PSI. 316 SS mat. Learn MoreAs low as $3.50

-

P.R.V.The P.R.V. are available for 2IN, 3IN and 4IN TC vent. Full 304 stainless steel body construction. Learn MoreAs low as $312.00

-

Circuit BreakerA circuit breaker is a safety device designed to protect electrical circuits from overcurrents and short circuits. It automatically interrupts the flow of electricity when it detects an abnormal condition, such as a surge or overload, to prevent damage to the wiring or appliances. Circuit breakers are commonly found in electrical panels and play a crucial role in ensuring the safety and reliability of electrical systems. Learn MoreAs low as $50.00

-

PRESSURE GAUGE 0-100 PSI 2.5IN DIAL, REAR MOUNT, 1/4IN MNPT CONNThe range of a pressure gauge should be approximately twice the operating pressure of the vessel. Learn More$24.00

-

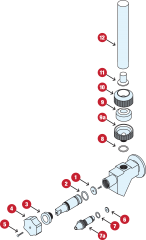

PRESSURE RELIEF VALVE, GUTH VENT, 0.9 LB, 3IN TC, (134-0105)The P.R.V. attaches to a 3IN TC vent. Valve relieves pressure as the fluid level rises while filling a tank Valve relieves vacuum as the fluid level drops while emptying a tank Seals under equal pressure Full body 316 stainless steel construction 1/4" FNPT connection for gas inlet, plug is included Vacuum break: , 0.1 PSI Pressure relief: 0.9 PSI Maximum temperature and pressure rating: 3 PSI @ 70°F Maximum flow rate: 500 GPM Learn More$312.00

-

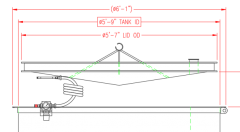

Floating Lid TubeTubes are designed for ICC NW varying capacity storage tanks. Please consult chart for correct size, questions please call (503) 468-6560. Our tube forumla changed in 2021. Learn MoreAs low as $0.64

-

(12) Sight Tube round5/8IN OD. Price below is per foot. To order please chose Qty: 1 foot = Qty 1 LEVEL GAUGE MUST BE ORDERED SEPARATELY Learn More$10.75

-

SIGHT GLASS, IN-LINE, 1.5IN (4-BOLT STYLE)SIGHT GLASS, IN-LINE, 1.5IN (4-BOLT STYLE) Learn More$142.40

-

RATE INDICATOR-COUNTER 6 DIGIT GEM2 20160 GEMINI 2000 SERIESRATE INDICATOR-COUNTER 6 DIGIT GEM2 20160 GEMINI 2000 SERIES Learn More$700.00

-

(1) DOOR PLATE-OVAL GRAIN OUT MANWAY 304Door plate will fit 16x22IN oval grainout manway Learn More$684.81